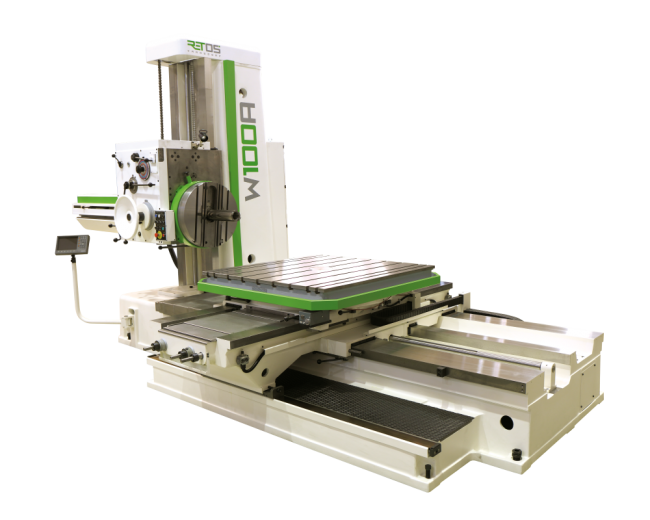

W100A CONVENTIONAL HORIZONTAL BORING MILL - TABLE TYPE

- the last conventional machine standardly produced by TOS VARNSDORF

- solid design

- travel in the X axis = 1600 mm

MAIN PARAMETERS

| Workspindle diameter | 100 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range | 1120 | rpm |

| Table transversal travel (X) | 1600 | mm |

| Headstock travel (Y) | 1120 | mm |

| Table longitudinal travel (Z) | 810 / 1250 / 1750 | mm |

| Spindle stroke (W) | 900 | mm |

| Table clamping surface | max. 1500 x 1500 | mm x mm |

| Table loading capacity | max. 3000 | kg |

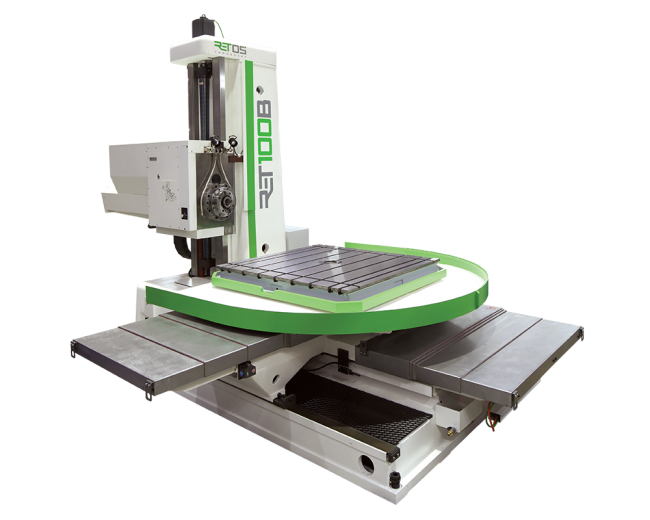

RET100B HORIZONTAL BORING MILL - TABLE TYPE

- solid design

- travel in the X axis = 1600 mm

- optionally automatic toolchanger with a tool changing time of 15 s (from cut to cut)

MAIN PARAMETERS

| Workspindle diameter | 100 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range | 3000 | rpm |

| Table transversal travel (X) | 1600 | mm |

| Headstock travel (Y) | 1220 | mm |

| Table longitudinal travel (Z) | 900 / 1710 | mm |

| Spindle stroke (W) | 710 | mm |

| Table clamping surface | max. 1500 x 1500 | mm x mm |

| Table loading capacity | max. 5000 | kg |

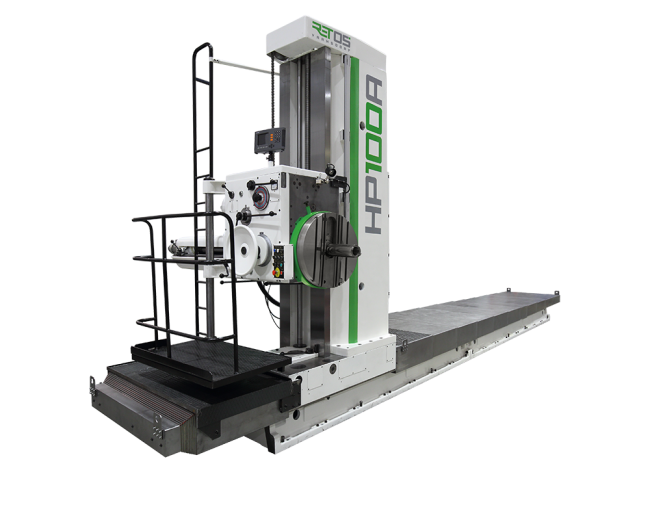

HP100A CONVENTIONAL HORIZONTAL BORING MILL - FLOOR TYPE

RET10X T-TYPE HORIZONTAL BORING MILL

- Maximum variability – unit principle

- Choose travel range of basic axes Y, Z max. 2,000 mm, X max. 3,000 mm

- Rolling guideways for all axes

- Ram headstock

- Choose size and number of clamping plates / tables

- Wide range of technological accessories

MAIN PARAMETERS

| Ram cross section | 315 / 380 | mm |

| Workspindle diameter | 105 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range | 3500 | rpm |

| Table transversal travel (X) | max. 3000 | mm |

| Ram/headstock travel (Y) | max. 2000 | mm |

| Column longitudinal travel (Z) | max. 2000 | mm |

| Ram stroke (V) | 650 | mm |

| Spindle stroke (W) | 610 | mm |

| Table clamping surface | max. 1500 x 1500 | mm x mm |

| Table loading capacity | 8000 | kg |

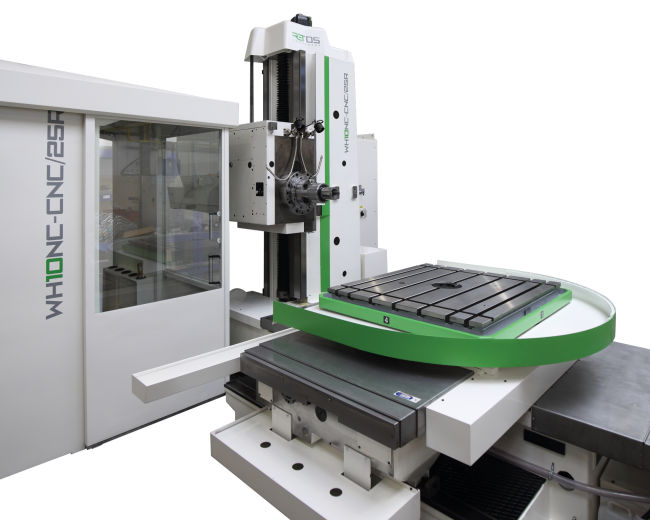

WH10-CNC HORIZONTAL BORING MILL - TABLE TYPE

- no matter what the original type is (from WHN9A to WH10CNC) the machine after upgrade reaches parameters comparable to a new one

- new or upgraded headstock up to 2500 rpm

MAIN PARAMETERS

| Workspindle diameter | 100 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range | 10 - 2500 | rpm |

| Transversal table travel (X) | 1200 | mm |

| Vertical headstock travel (Y) | 900 / 1150 | mm |

| Longitudinal table travel (Z) | 950 | mm |

| Spindle stroke (W) | 710 | mm |

| Table clamping surface | 1000 x 1120 | mm x mm |

| Table loading capacity | 3000 | kg |

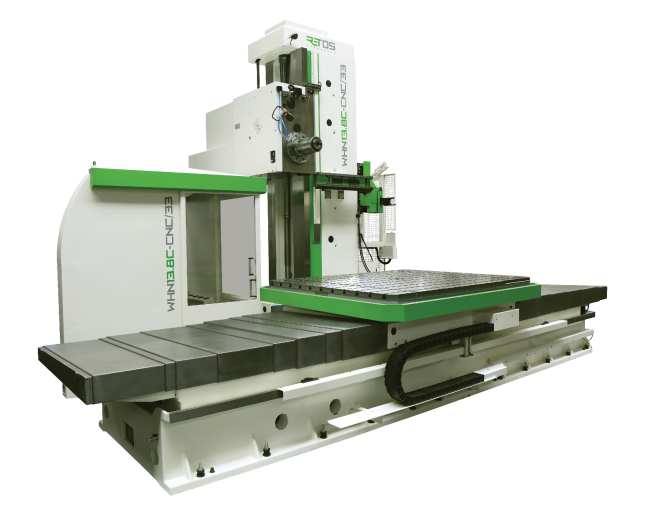

WHN13-CNC HORIZONTAL BORING MILL - T TYPE

- cross-shaped beds

- no matter what the original type is (from WH13 to WHN13-CNC) the machine after upgrade reaches parameters comparable to a new one

- new headstock up to 3300 rpm

- optionally fitted with automatic toolchanger with tool changing time of 10 s (from cut to cut)

MAIN PARAMETERS

| Workspindle diameter | 130 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range | max. 3300 | rpm |

| Table transversal travel (X) | 2000 / 3500 | mm |

| Headstock travel (Y) | 2000 / 2500 / 3000 | mm |

| Column longitudinal travel (Z) | 1250 | mm |

| Spindle travel (W) | 800 | mm |

| Table clamping surface | max. 1800 x 2200 | mm x mm |

| Table loading capacity | 12000 | kg |